Rig rigidity questions

-

The configuration of the 5 line rig is reliant on the rigidity of the structure. How easy are people finding this to maintain? and what impact, if any are they seeing on the lifespan of their grow lines?

To provide a reference point to any answers, I would be interested in knowing the years of rig operation, number of rigs operated, estimate of site exposure and types of rope used.

I question this because I anticipate that the rigidity of rigs would be hard to maintain in exposed sites, with certain ropes or at the greater than 50 rig scale. And even when maintaining the rigidity, the constant force exerted on the grow lines will significantly reduce their lifespan (i.e. by at least one season).

Iskander, for what I think are good reasons, I disagree with your suggestion that lines under constant force have reduced lifespan. It may be true if the line is held at or close to its breaking strength. But in these rather elastic farm systems, that’s simply not the case. I’ve seen no indication that growline lifespans are reduced in multi-line rigs and suspect we will learn quite the opposite in time.

Chafe and sunlight are the enemies of lines. While the justification for adopting multi-line farm systems is to increase crop density and therefore productivity per acre, that goal is enabled by providing uniform growline tension across the rig, allowing close line spacing. Of course, this requires precise line measurements and proper rigging along with attention during the season to counteract line creep, increased crop weight, and any anchor movement.

Done right, lines ought not be touching each other and when constructed right using splices and no knots, the only remaining wear issue is associated with the hauling and cutting process. Off-season storage out of the sun goes without saying.

As far as types of line, 3-strand poly/dac blends seem most popular. Hydropro is a neutrally buoyant brand and comes in several sizes and lays (stiffness). https://www.friendshiptrap.com/index.php?/Polysteel-Hydropro-Pro/506-3/8-Hydropro-Md/So-Inside/Out-Pot-Warp.html

You are right, maintaining the desirable pre-tension in these multi-line rigs can be challenging compared to simply fussing with a single-line rig. We’ve found novel deadeye tensioners to be just the ticket for the 5-line spreader rigs as well as the bigger catenary modules. Like an underwater block & tackle, it’s pretty easy to take in any slack from the system and its also easy to add slack for inspections or harvesting.

Cliff

@clifford_goudey thanks again for the insight. I see that the loads in comparison to the breaking strength of the rope has been missing from my reading on rope creep. Do you have some literature that you base the "at or close to breaking strength" statement on?

I am under the impression that the tension needed to prevent the entanglement of what look to be between 1 - 2 m spaced grow lines with spreader bars every 30 m is a large enough force to keep most ropes in the secondary creep phase (as defined by Samson ropes, https://www.samsonrope.com/resources/general/understanding-creep). What diameter and type of rope, exposure conditions of the site, overall length of grow line and years of rope use are you basing your assessments on?

We have not yet reached the end of the lifespan of the ropes we use at a moderately exposed site (target lifespan: 15 seasons, site coords: 56.3681,-5.5346, rope used: ~12mm 3-strand hydropro equivalent). We do anticipate they will eventually deteriorate due to the continued striping of the holdfasts and wear from residual salt crystals (fresh water baths can/should only go so far). I will temporarily be content if the creep exerted by adding tension to our lines would not reduce the lifespan below our target.

Iskander, please pardon the delay in responding. My basis for mentioning “at or close to breaking strength” was not relate to creep issues but rather that inevitable jerk loads would eventually cause rupture. The pretension loads needed to control growline sag are not that high, maybe 2% to 5% of breaking strength and are typically less than what current drag routinely impose on those lines when loaded with crop.

Creep of lines came to the forefront with the introduction of high-modulus lines such as dyneema and in applications where small diameter, length stability, or low drag was pivotal (winches, halyards, guy wires, trawl twine, etc.) I don’t see much applications for them in seaweed farming, as elastic stretch is useful in absorbing loads and accommodating tidal variations. Besides, they are way too expensive outside of niche applications..

Most of the farms I’m aware of are using either 3/8” (9mm) or 1/2” (12mm) and typically 3-strand poly/dac blends. Using such lines, commercial growline lengths range from 200’ to 800’. I’m sure longer lengths have been tried, however at some point more length will require stronger line and the economics turn sour.

In funded research projects we typically do a techno-economic analysis, which required some knowledge or estimation of farm component longevity. We typically guess 5 years for growlines but have insufficient experience to really know. I think 10 years is a conservative number for other structural lines that do not see the handling imposed on growlines. In the end, I think farming will see far longer service life than the fishing applications where they must endure frequent hauling and lots of chances for sand and grit to get in the fibers.

@clifford_goudey thanks again for the insight. I see that the loads in comparison to the breaking strength of the rope has been missing from my reading on rope creep. Do you have some literature that you base the "at or close to breaking strength" statement on?

I am under the impression that the tension needed to prevent the entanglement of what look to be between 1 - 2 m spaced grow lines with spreader bars every 30 m is a large enough force to keep most ropes in the secondary creep phase (as defined by Samson ropes, https://www.samsonrope.com/resources/general/understanding-creep). What diameter and type of rope, exposure conditions of the site, overall length of grow line and years of rope use are you basing your assessments on?

We have not yet reached the end of the lifespan of the ropes we use at a moderately exposed site (target lifespan: 15 seasons, site coords: 56.3681,-5.5346, rope used: ~12mm 3-strand hydropro equivalent). We do anticipate they will eventually deteriorate due to the continued striping of the holdfasts and wear from residual salt crystals (fresh water baths can/should only go so far). I will temporarily be content if the creep exerted by adding tension to our lines would not reduce the lifespan below our target.

Iskander, please pardon the delay in responding. My basis for mentioning “at or close to breaking strength” was not relate to creep issues but rather that inevitable jerk loads would eventually cause rupture. The pretension loads needed to control growline sag are not that high, maybe 2% to 5% of breaking strength and are typically less than what current drag routinely impose on those lines when loaded with crop.

Creep of lines came to the forefront with the introduction of high-modulus lines such as dyneema and in applications where small diameter, length stability, or low drag was pivotal (winches, halyards, guy wires, trawl twine, etc.) I don’t see much applications for them in seaweed farming, as elastic stretch is useful in absorbing loads and accommodating tidal variations. Besides, they are way too expensive outside of niche applications..

Most of the farms I’m aware of are using either 3/8” (9mm) or 1/2” (12mm) and typically 3-strand poly/dac blends. Using such lines, commercial growline lengths range from 200’ to 800’. I’m sure longer lengths have been tried, however at some point more length will require stronger line and the economics turn sour.

In funded research projects we typically do a techno-economic analysis, which required some knowledge or estimation of farm component longevity. We typically guess 5 years for growlines but have insufficient experience to really know. I think 10 years is a conservative number for other structural lines that do not see the handling imposed on growlines. In the end, I think farming will see far longer service life than the fishing applications where they must endure frequent hauling and lots of chances for sand and grit to get in the fibers.

Iskander, I should also point out that the term “rigidity” may be a poor choice. By design, these systems have all the flexibility of other rigs. A better description would be “uniformity of tension.” That’s something that cannot be obtained in independent single line rigs, and that is why those rigs need to be placed a good distance apart.

These systems are not rigid since they retain all the elasticity of the line from which they are built. In the case of Hydropro, that’s 18% elongation at failure. As long as the neighboring lines have the same stress/strain relationship and their lengths are as prescribed by the catenary calculations, then you have the desired outcome with little chance of line interference.

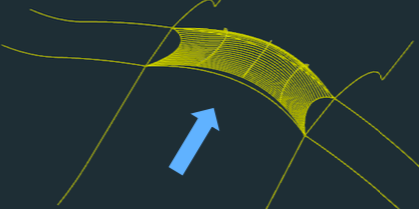

In the image below from catenary module simulations done by DSAOcean we see an extreme current coming in at 90˚ to the growlines yet the proper spacing is retained even though the whole farm has become distorted by hydrodynamic drag. The line loads in this case dwarf whatever initial pretension loads were established to control vertical sag.

Cliff

@clifford_goudey Thank you for those answers. 2.7ft is an impressive spacing to maintain under such conditions. What species are being farmed on this rig? With similar spacing, I have observed near harvest growth of Alaria esculenta wrap itself around adjacent lines whilst the lines themselves were not entangled.

Is that to within an inch accuracy for just the grow lines? Or for every line used to construct the rig?

I am sorry to hear that. If the rig has survived in at least an easily recoverable state, I will cease all other questions but “How much for one of our own?”

Iskander, 2.5’ to 2.7’ spacing has been used for Saccharina latissima and yes, sometimes the fronds can reach across to interact with neighbors, but that seems a natural phenomenon. It clears itself in time and if not, it does not interfere with harvest or production levels.

The accuracy demands of line length measurements are confined to the growlines, the growline extension, the catenary line, the spacing of the connections along the catenary, and the transverse framing line. Anchor lines and longitudinal framing lines are less demanding and usually include a deadeye tensioning system to manage growline tension.

So far with these catenary lines we have confined major failures to our simulations. The farm in La Parguera, Puerto Rico that was installed in July just survived a direct hit from hurricane Fiona. With the lingering power outages and poor comms, we don’t yet know the details, but the news was a great relief.

@clifford_goudey thank you again for this insight. I believe I have been overestimating the pretention loads that are being imposed on the lines. The substantial creep I have seen in the past was when using ropes more suitable to the binder seeding method. It has been my assumption that all ropes used as a growline would undergo some continuous creep, but it is just not as apparent across a few season for hydropro.

There are very few western companies who have completed five seasons at sea. Fewer still who would have been using the same ropes for that time. And probably none who would have been using the same ropes as each other in the same configuration in equivalent conditions and with the same care. We have undergone a vast array of changes since our trials began in 2016, and only in the past few seasons have we been able to begin testing the longevity of our grow lines. 15 years is a target borne from the anticipated required cost of production to meet the market price of a larger scale industry.

I appreciate that this simulation further demonstrates the point that the pretension load is less significant than other forces the lines will be subjected to. What was being deemed as appropriate spacing in this simulation of the catenary rig?. Do you know how resilient such a design is to anchor drag, both grow line and structural line failures, and line lengths diverging from those prescribed by the calculations?

Iskander, you asked, "What was being deemed as appropriate spacing in this simulation of the catenary rig?"

You asked, "Do you know how resilient such a design is to anchor drag, both grow line and structural line failures, and line lengths diverging from those prescribed by the calculations?"

Iskander, you asked, "What was being deemed as appropriate spacing in this simulation of the catenary rig?"

You asked, "Do you know how resilient such a design is to anchor drag, both grow line and structural line failures, and line lengths diverging from those prescribed by the calculations?"

@clifford_goudey Thank you for those answers. 2.7ft is an impressive spacing to maintain under such conditions. What species are being farmed on this rig? With similar spacing, I have observed near harvest growth of Alaria esculenta wrap itself around adjacent lines whilst the lines themselves were not entangled.

Is that to within an inch accuracy for just the grow lines? Or for every line used to construct the rig?

I am sorry to hear that. If the rig has survived in at least an easily recoverable state, I will cease all other questions but “How much for one of our own?”

Iskander, 2.5’ to 2.7’ spacing has been used for Saccharina latissima and yes, sometimes the fronds can reach across to interact with neighbors, but that seems a natural phenomenon. It clears itself in time and if not, it does not interfere with harvest or production levels.

The accuracy demands of line length measurements are confined to the growlines, the growline extension, the catenary line, the spacing of the connections along the catenary, and the transverse framing line. Anchor lines and longitudinal framing lines are less demanding and usually include a deadeye tensioning system to manage growline tension.

So far with these catenary lines we have confined major failures to our simulations. The farm in La Parguera, Puerto Rico that was installed in July just survived a direct hit from hurricane Fiona. With the lingering power outages and poor comms, we don’t yet know the details, but the news was a great relief.